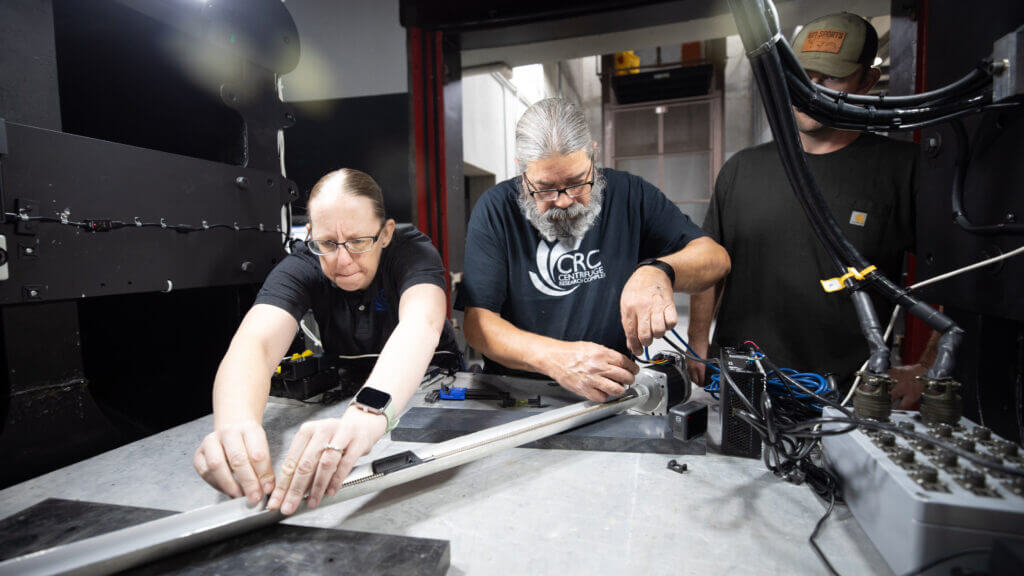

ERDC’s Centrifuge Research Complex undergoes innovative upgrades

Upgrades were recently completed to one of the world’s most powerful beam centrifuges, giving modernized functionality to one of the most innovative pieces of technology at the U.S. Army Engineer Research and Development Center (ERDC).

The centrifuge, housed in ERDC’s Centrifuge Research Complex (CRC) within the Geotechnical and Structures Laboratory’s (GSL) Geotechnical Engineering and Geosciences Branch (GEGB), received improvements to its electrical and hydraulic systems, along with major renovations to the control building. The upgrades support a larger research staff, enable better collaboration with outside organizations and technologically enhance control between the centrifuge’s on-board systems and researchers.

A centrifuge model is scaled down from real-world prototypes that include research areas such as large infrastructural issues too difficult to model at full scale such as dams, levees, tunnels, retaining walls, offshore platforms, and much more. The centrifuge can also speed up processes that take significant time to replicate such as clay consolidation, ecosystems and soil contamination.

“The centrifuge helps inform engineering solutions without using excessive resources, which is more cost effective and more efficient,” said Ryan Bockman, a CRC engineering technician. “Additionally, the answers that come out of the centrifuge tests have real-world impacts, such as keeping people safe from levee failure, for example.”

Centrifuge research applies to many scalable problems, and research incorporates unique capabilities and capitalizes on the customer’s knowledge to bridge the gap between lab and field scale. The centrifuge can scale gravity to match real-world conditions in a controlled facility model complex structures, systems and phenomena.

Building upon the centrifuge’s assets gives the machine added resources that engineers and scientists could apply to future, current and past studies.

“Included in the latest updates are technological innovations important to centrifuge testing in the last 10 years, giving us many more tools and flexibility to collect all kinds of measurable data for researchers using the centrifuge,” said Dr. April Bowman, a research civil engineer at the CRC. ERDC is home to the Centrifuge Research Complex, which supports research investigations under a wide range of conditions.

Bowman believes the upgraded capabilities allow the machine to perform at groundbreaking levels.

“The changes have improved the reliability of the centrifuge and modernized how we control experiments and collect data,” said Bowman. “The changes make things like high-speed photography results instantaneously available to researchers in the control room without stopping the centrifuge. These improvements give us more tools and flexibility to collect measurable data for researchers.”

Engineers praise the centrifuge’s efficiency, which leads to the machine’s ability to solve real-world challenges. The centrifuge’s ability to analyze real-world scenarios before they occur also provides engineers with the necessary tools to solve problems when they arise.

“Because the centrifuge allows for replication of different processes in a controlled and repeatable environment, engineering solutions can be tested before being implemented in the field,” said Joelle Westcott, a CRC research civil engineer. “This means the centrifuge allows for innovation and creative solutions for safe and reliable infrastructure, which is an increasing necessity due to continuous environmental changes.”

For Bockman and Wescott, having the chance to lend their expertise to the machine is a valuable experience.

“It’s cool working at the CRC. I like that I can apply my diverse background in construction to help solve some of the world’s engineering problems,” said Bockman.

“What I love most about the job is the diverse projects, capabilities, and research our centrifuge can do. We can tackle so many different problems,” said Westcott.